Trail-Tested Truck Bumpers – Steel or Aluminum for Ultimate Protection?

When your truck meets unforgiving terrain, a rock-hard Jeep bumper is indispensable. The aluminum vs steel bumper debate affects trail performance, cost, and vehicle handling. This guide examines real trail-damage data, ownership costs, and practical DIY tips for any bumper upgrade decision. We’ll break down materials, durability testing, and long-term expenses, whether you need extra protection or front and rear bumper coverage.

Metal Basics – How Steel and Aluminum Bumpers Are Built

Understanding how manufacturers build aluminum and steel bumpers reveals why each sample performs differently. The distinction between these bumpers affects durability, weight, and cost.

| Steel | Aluminum |

| Alloy Types: High-carbon, mild steel, chromoly for durable construction | Alloy Types: 6061-T6, 5052-H32 marine grade lightweight aluminum |

| Thickness: 3/16″ to 1/4″ plate typical, thicker for heavy-duty use | Thickness: 1/4″ to 3/8″ for comparable strength |

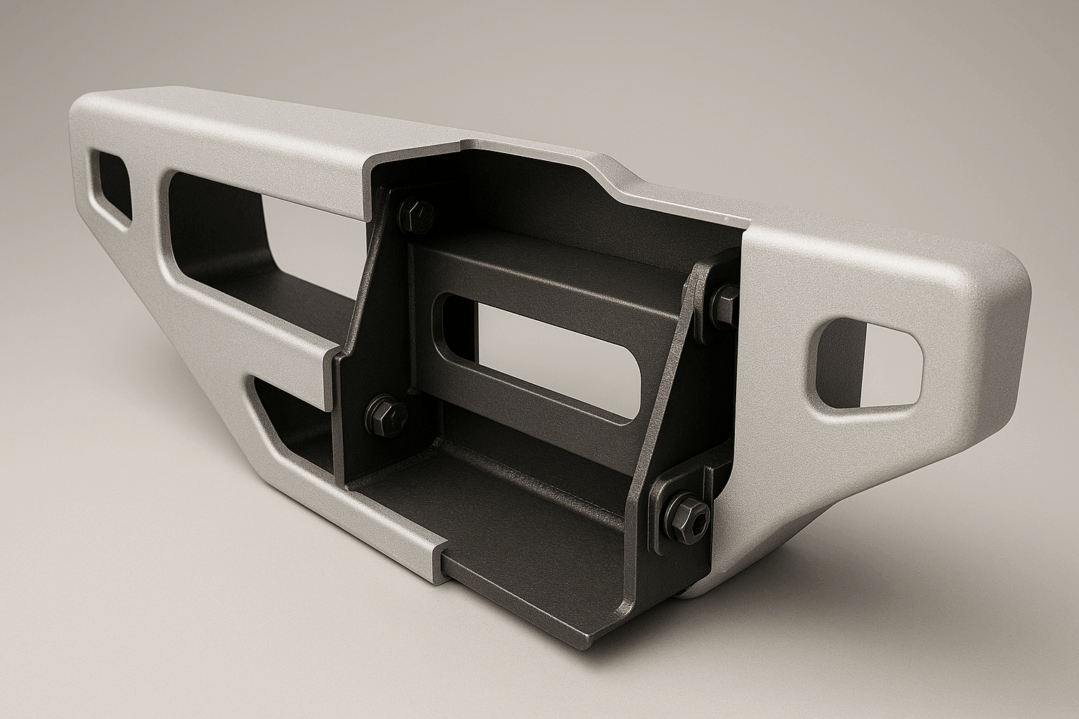

| Construction: TIG/MIG welded joints, custom-built fabrication | Construction: Extruded sections, welded assembly |

| Heat Treatment: Stress-relieved after welding to prevent wear and tear | Heat Treatment: T6 temper for maximum strength without weight |

| Recyclability: 90%+ steel content recoverable | Recyclability: 95%+ aluminum is infinitely recyclable |

Strength & Impact Resistance on the Trail

Real-world testing reveals significant distinctions between bumpers when your truck meets rocks or obstacles during off-roading.

| Test Parameter | Steel | Aluminum |

| Tensile Strength | 65,000-80,000 PSI | 45,000 PSI (6061-T6) |

| Yield Strength | 36,000-50,000 PSI | 40,000 PSI |

| Impact Behavior | Dents, stays intact without wear | May crack but absorbs energy |

| Winch Capacity | 12,000+ lbs is typical for steel construction | 9,500 lbs (with reinforcement plates) |

“In twenty years of building custom-built stuff for off-roading, I’ve seen aluminum ones take hits that would bend steel, but steel bumper protects against repeated impacts better,” explains Jake Morrison, owner of Rocky Mountain Fabrication. “Choose steel to get extra protection.”

Moab examples show steel bumpers developing surface damage while maintaining integrity for continued protection. An aluminum sample may crack through, but it often prevents frame damage by absorbing impact energy more effectively. The style of impact matters. Aluminum protects better against a single severe hit. A steel bumper handles multiple smaller impacts that could bend lesser materials during intense off-roading sessions.

Weight, Handling & Fuel Economy

⚠️ Adding heavy steel bumper protection affects vehicle dynamics and may exceed GVWR limits on some vehicles.

The weight difference between bumpers creates measurable performance impacts:

- Steel bumper options typically weigh 80-120 pounds for front bumper applications

- Aluminum alternatives weigh 25-40 pounds for comparable protection

- Steel is roughly 3× heavier than comparable aluminum construction

- Expect a 1-2 MPG reduction with steel front and rear bumper installations

- Suspension preload increases, affecting ride quality and component wear

- Braking distances may increase 5-10 feet from 60 mph with heavy steel protection

- GVWR considerations become critical when adding winch gear and other stuff

Aluminum options help save weight while maintaining trail capability, especially important for daily-driver truck applications where economy matters. The difference becomes more pronounced with rear bumper additions and auxiliary racks during extended off-roading adventures.

Corrosion, Coatings & Maintenance

Maintenance Checklist:

- Inspect the coating monthly for chips or scratches that expose the base materials

- Touch up bare steel within 48 hours of damage to prevent rust formation

- Apply marine wax in coastal environments for more protection

- Check mounting hardware for corrosion signs and replace if needed

- Inspect paint finish regularly for damage from off-roading debris

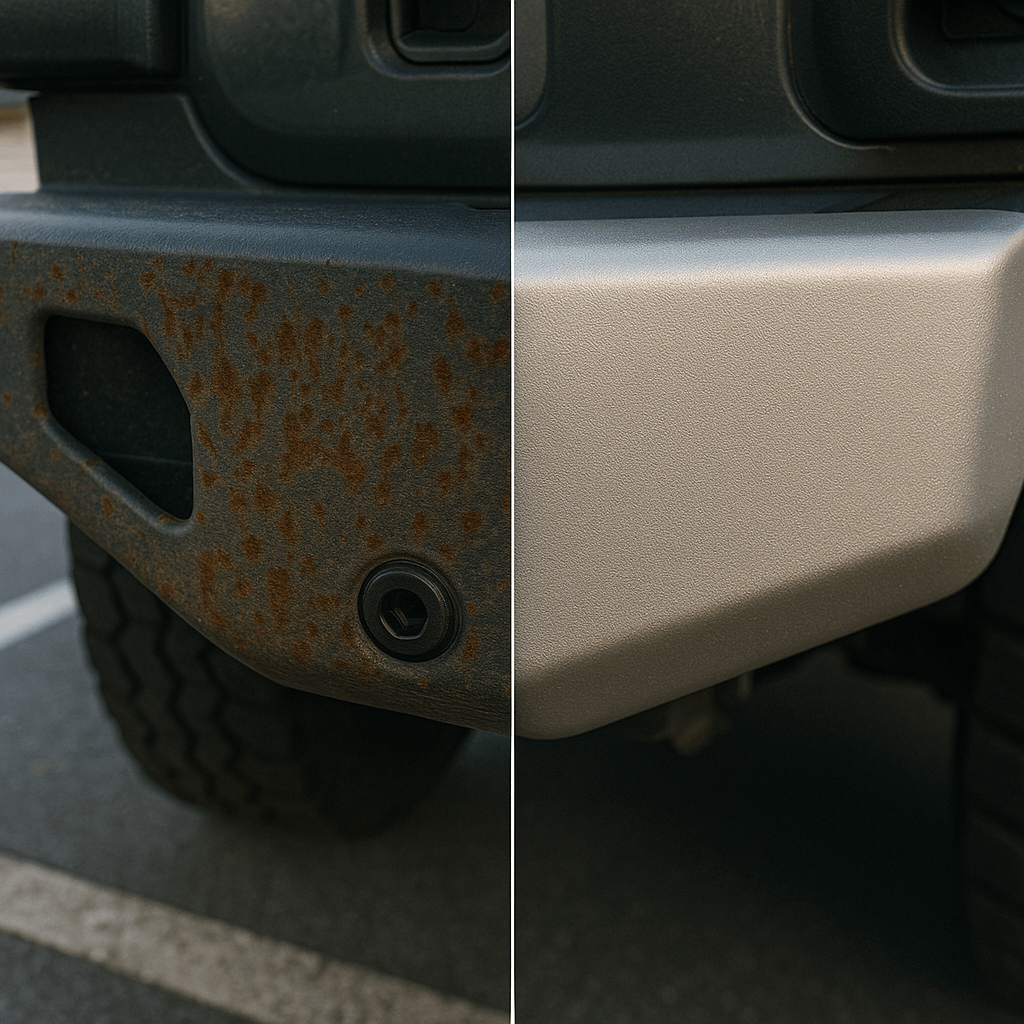

Steel bumper faces rust challenges requiring regular maintenance, while aluminum develops galvanic corrosion when mixed with dissimilar materials. Coastal salt creates aggressive environments where aluminum bumpers’ natural resistance provides advantages over steel bumpers.

Quality powder coating protects the steel bumper effectively, but any paint damage requires immediate attention. Over five years, maintenance expenses favor the light metal due to reduced touch-up requirements. Unlike front bumpers, rear bumpers face additional challenges from road debris during aggressive off-roading.

Dollar Math – Purchase Price to Long-Term Cost of Ownership

| Expense Category | Steel Bumper | Aluminum Bumper |

| Initial Purchase | $800-2,200 (cheaper entry) | $1,200-3,500 (premium expenses) |

| Installation Labor | $200-400 | $250-450 |

| Suspension Upgrades | $400-800 (often needed) | $0-200 (rarely needed) |

| 5-Year Maintenance | $150-300 (rust prevention) | $50-100 (minimal upkeep) |

| Resale Impact | +$400-600 | +$600-1,000 |

💡 Steel bumper installations often require modifications to handle additional weight. This adds $400-800 to the total project expenses. Factor springs upgrades into budget planning.

Aluminum costs more upfront. However, it delivers better long-term value. It’s due to reduced maintenance and higher resale values. The price difference narrows when factoring complete ownership experience rather than just the initial purchase price. Many truck owners find that choosing a steel bumper appears cheaper initially, but the other sample proves more economical over time.

Accessory & Sensor Compatibility

Compatibility Checklist:

- Parking sensor relocation brackets are included for proper vehicle integration

- Radar cruise control module clearance verified for safety systems

- Adaptive headlight mounting preserved for original functionality

- Factory fog light integration is possible with OEM-style mounting

- Winch mounting rated for intended load capacity and gear requirements

⚠️ Aftermarket bumper options must maintain proper crush-zone characteristics. It helps avoid airbag deployment issues. Before installing any front bumper or rear bumper protection, verify compatibility with your vehicle’s safety systems .

Modern vehicles integrate multiple sensors into factory bumper assemblies. Quality aftermarket steel and aluminum bumpers relocate these systems properly while maintaining functionality, while cheaper alternatives may require expensive modifications. Steel and aluminum bumpers both accommodate sensor relocation, though the latter’s reduced weight creates less stress on mounting points. Utilizing aftermarket safety tools without proper sensor integration can trigger warning lights and disable critical safety features.

Choosing the Right Material for Your Rig

Steel Bumper Pros & Cons:

Pros:

- Maximum impact strength

- Lower initial expenses

- Easier repair options

- Wider style selection

- Better safety

- Durable construction

Cons:

- Heavyweight affects the economy

- Rust potential in harsh environments

- Modifications are often needed

Aluminum Bumper Pros & Cons:

Pros:

- Lighter weight improves handling

- Excellent resistance

- Better economy

- No upgrades required

- Premium appearance

Cons:

- Higher initial expenses

- Limited repair options in remote areas

- Fewer custom choices are available

- Potential cracking under extreme impacts

Climate considerations matter for long-term durability and maintenance. Desert environments favor either choice, while coastal regions benefit from aluminum ones’ resistance. Payload needs determine whether weight savings justify aluminum expenses, especially when adding winch systems. Jeep owners often prefer a steel bumper for rock crawling. Truck owners who focus on overlanding frequently choose an aluminum bumper for better fuel economy.

Installation Tips & Safety Checks

- Preparation 🔧 Remove the original bumper and disconnect electrical connections, preserving original hardware for reuse

- Mounting 🔧 Install new steel or aluminum bumper brackets using OEM torque specifications exactly as specified

- Electrical ⚡ Reconnect sensors and lighting per the manufacturer’s instructions, ensuring proper vehicle integration

- Winch Setup 🔧 Route through designated fairlead openings, avoiding sharp edges that could cause tear damage

- Calibration 📱 Reset airbag sensors using an OBD scanner if required by the installation process

- Final Check ✅ Verify all bumper mounting hardware reaches proper torque values and inspect for clearances

🔧 Always use proper lifting equipment and follow torque specifications exactly during the installation process. Improper installation affects crash safety systems.

Post-installation inspection should verify no interference with proper electrical connections and secure bumper mounting at all attachment points. Test all original safety systems before first trail use to ensure complete functionality. Both bumpers require identical installation procedures. However, lightweight aluminum’s reduced weight makes handling easier. Check that rear bumpers don’t interfere with spare tire carriers or trailer hitch receivers.

Environmental Footprint & End-of-Life Recycling

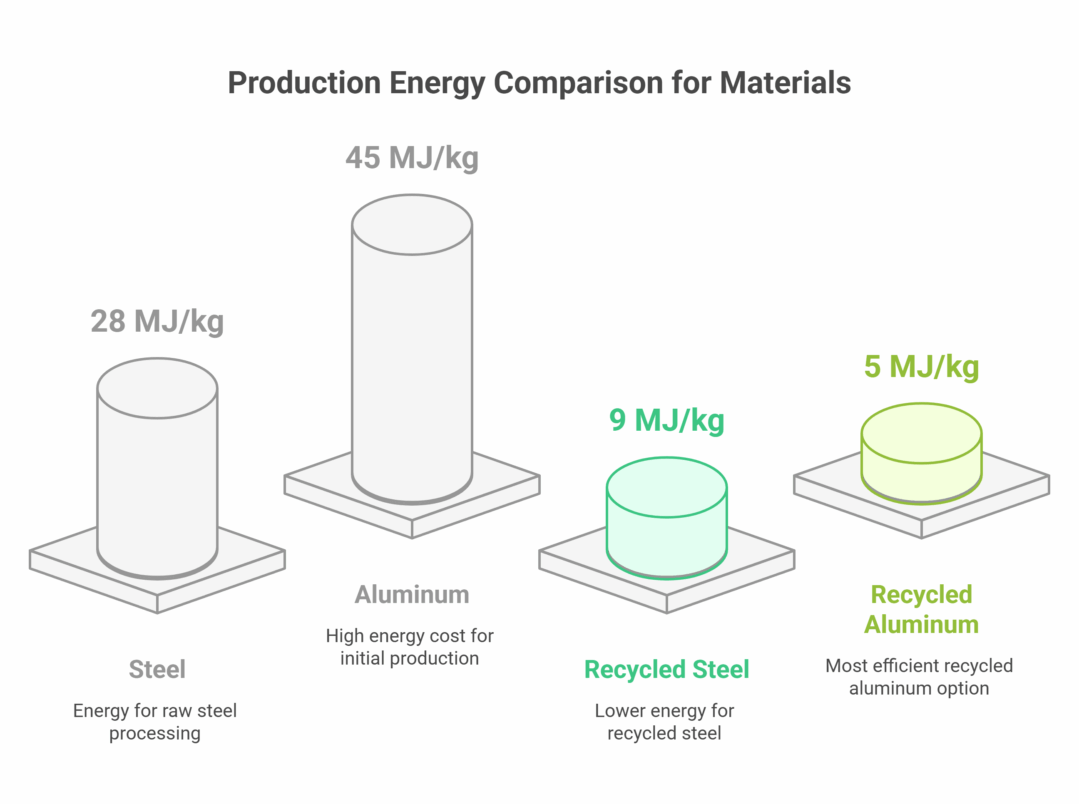

Environmental Considerations:

- Aluminum requires more energy to produce initially, but it recycles infinitely without quality loss

- Steel production generates more CO2 emissions, but uses abundant raw materials from the Earth

- Weight reduction saves fuel over the lifetime, offsetting production expenses

- Both materials achieve 90%+ recycling rates at the end of life

- Lighter samples reduce tire wear and brake pad consumption

Long-term environmental impact favors aluminum through reduced fuel consumption and superior recyclability, despite higher initial production energy requirements. The distinction becomes more significant over a lifetime, especially for daily-driver applications where fuel savings accumulate substantially.

FAQ – Steel vs. Aluminum Bumpers

Is aluminum or steel better for bumpers?

Steel wins on raw impact strength. Aluminum bumpers excel in weight savings and resistance. Therefore, choose based on terrain and load.

What are the disadvantages of a steel bumper?

Extra weight, potential rust, and possible need for suspension upgrades.

What is the best metal for a bumper?

For brutal rock crawling, high-grade steel; for better overlanding, 6061-T6 aluminum works well.

Does a steel bumper hurt gas mileage?

Yes. Expect a 1–2 MPG drop on midsize trucks due to added mass.

Can aluminum bumpers handle winches?

Yes, if they have steel or boxed-aluminum plates.

Will either material affect airbag sensors?

Poorly designed aftermarket mounts can. Always use bumpers that retain OEM crush-zone specs.

How do hybrid bumpers work?

They pair a steel cradle with an aluminum shell. This step helps combine strength with lightness.

Are powder-coated steel bumpers truly rust-proof?

Coating delays rust. Nonetheless, chips or drilled holes must be resealed.